Extreme Airport Engineering

Season 52 Episode 2 | 53m 40sVideo has Audio Description, Closed Captions

Follow the race to build a world-class airport on the site of one of America’s busiest flying hubs.

In New York City, a team of elite engineers and construction workers are on a mission to build the ultimate airport. Follow their ups and downs as they race to build a new, world-class LaGuardia on the site of one of America’s busiest aviation hubs.

See all videos with Audio DescriptionADProblems playing video? | Closed Captioning Feedback

Problems playing video? | Closed Captioning Feedback

Additional funding for this program is provided by the NOVA Science Trust with support from Margaret and Will Hearst and the Hoveida Family Foundation. National Corporate funding for NOVA is...

Extreme Airport Engineering

Season 52 Episode 2 | 53m 40sVideo has Audio Description, Closed Captions

In New York City, a team of elite engineers and construction workers are on a mission to build the ultimate airport. Follow their ups and downs as they race to build a new, world-class LaGuardia on the site of one of America’s busiest aviation hubs.

See all videos with Audio DescriptionADProblems playing video? | Closed Captioning Feedback

How to Watch NOVA

NOVA is available to stream on pbs.org and the free PBS App, available on iPhone, Apple TV, Android TV, Android smartphones, Amazon Fire TV, Amazon Fire Tablet, Roku, Samsung Smart TV, and Vizio.

Buy Now

NOVA Labs

NOVA Labs is a free digital platform that engages teens and lifelong learners in games and interactives that foster authentic scientific exploration. Participants take part in real-world investigations by visualizing, analyzing, and playing with the same data that scientists use.Providing Support for PBS.org

Learn Moreabout PBS online sponsorship♪ ♪ NARRATOR: In New York City, designers, engineers, and construction workers... DAN MURPHY: Watch the boom!

NARRATOR: ...are on a once-in-a-lifetime mission to build an extraordinary airport.

TONY VERO: We didn't realize the magnitude of what we were going to be up against.

NARRATOR: The city's new LaGuardia Airport has a budget of more than $8 billion and will be America's first new airport in more than 25 years.

RICK COTTON: The United States has fallen way behind in terms of infrastructure.

CARMELA CINICOLO A new LaGuardia is something that we always knew we needed.

NARRATOR: While planes continue to fly, 7,000 workers must completely rebuild the old airport here, to create a brand-new fully connected facility that can handle more than 34 million passengers every year.

RYAN MARZULLO: This is such a massive program, how are we going to pull this off?

JESSICA FORSE: It's a 24/7 operation, all hands on deck.

NARRATOR: To meet this enormous engineering challenge, the team will battle extreme weather... KEVIN GILLEN: Probably the worst storm we've seen in five years.

ANA TIMOVA: Being out on the steel while it's wet?

Very dangerous.

NARRATOR: ...and control massive machines.

CINICOLO: One wrong move, we could strike a building.

NARRATOR: Can they complete one of New York's largest infrastructure projects in a generation, while keeping all the planes moving?

The likelihood of the entire thing falling out of balance is very, very real.

NARRATOR: The exclusive inside story of "Extreme Airport Engineering."

Right now, on "NOVA."

♪ ♪ NARRATOR: New York, the city that never sleeps.

More than 120 million people fly in and out of the Big Apple each year.

GINNY ELLIOTT: Airline travel is in high demand, particularly in New York.

MAN (whistles): Taxi!

NARRATOR: In a city that seems in a perpetual hurry, commuters expect fast, efficient transportation.

CINICOLO: We're New York, we have to have the best of the best-- we should be leaders.

NARRATOR: So, this team of architects and engineers has designed America's first new airport in a quarter of a century.

MARZULLO: Well, this is once-in-a-generation, once-in-a-lifetime, once-in-a-career type of experience that we're about to embark on.

♪ ♪ NARRATOR: In 2016, New York's LaGuardia Airport, which sits to the east of Manhattan, is handling around 550,000 passengers each week.

But by 2030, it's expected to need capacity for almost 20% more.

So, the plan is to demolish the separate terminals and rebuild them, connected, 600 feet back, towards the edge of the site.

Twin pedestrian bridges will lead passengers to their gates.

40 acres of recovered space will enable new two-lane taxiways that let planes circulate freely.

It'll take 72,000 tons of steel and almost 600,000 tons of concrete.

But LaGuardia's new terminals will finally be fully unified, an airport fit for 21st-century travel.

Work on the new airport begins in June 2016, at this special groundbreaking ceremony.

This transformation can't come too soon for commuters here.

This is my first trip to LaGuardia and probably my last.

I don't want to come back.

NARRATOR: The old airport is run down and overcrowded.

So now there are two separate teams designing and building the airport, one for the new Terminal B and one for the new Terminal C, while the historic Art Deco Marine Air Terminal A-- built in the 1930s-- will be preserved to safeguard its unique architectural features.

The two terminal teams face a monumental challenge-- the size and shape of the site.

For a major airport, LaGuardia is small, and it can't get bigger.

It's hemmed in by water on one side and highways on the other.

There's no space to expand.

And to make their task even more difficult, the team must keep the airport fully operational throughout construction-- flights cannot be shut down.

DEREK THIELMANN: Closing the airport just isn't an option.

We have to find a way to maintain the existing operation and build, build new.

NARRATOR: As the team transforms the old airport, they must keep at least 66 gates operational.

At Terminal B, first they're building a new concourse with 18 new gates, and demolishing half of the old gates.

Then they'll repeat that on the other side: build and demolish.

At Terminal C, first they're building a completely new concourse on the water's edge with seven new gates.

Then they'll build and demolish the rest in stages.

♪ ♪ It's an ambitious nine-year plan, and they must keep the airport open for business while they work.

COTTON: All of LaGuardia would fit into Central Park with 150 acres to spare.

The construction project at LaGuardia is a ballet on a postage stamp.

There's simply no room.

NARRATOR: The lack of space and complex logistics force architects to design an innovative new layout for the new Terminal B.

♪ ♪ PETER RUGGIERO: As commercial air travel grew and expanded, the idea was, don't keep making it longer and linear, but simply start to fold it to create fingers.

The original plan for LaGuardia was a classic example of the finger design.

NARRATOR: During the 1960s, as more people flew, aircraft grew in size to hold more passengers.

But bigger airplanes mean that fewer can park around the finger-shaped concourses.

The inefficiency of the finger is found in these inside corners.

NARRATOR: Large aircraft can't easily maneuver in and out of these tight corners.

So, LaGuardia's new Terminal B will have a radically different shape.

It will use a satellite design.

RUGGIERO: On a freestanding satellite concourse, you can even park on the corners.

The airlines and the airport operators found great efficiencies in this design.

NARRATOR: The new design transforms the four fingers of the old Terminal B into two freestanding satellite concourses.

Aircraft can park all around the perimeter, with many different routes leading to the runway, reducing time on the tarmac.

Getting passengers from the new main terminal building to the concourses is more complex.

They could dig tunnels under the taxiways, but this would likely take years and add millions of dollars to the project.

The design team's audacious solution: two vast pedestrian bridges, so high above the tarmac that all aircraft here can pass beneath.

♪ ♪ First task-- before engineers can build the pedestrian bridges, they must construct the 850,000-square-foot main terminal building and two satellite gate concourses that the bridges will connect to.

CINICOLO: It may look crazy, but it's really a managed crazy.

That is the only way to a successful program and achieving these milestones.

♪ ♪ NARRATOR: Constructing LaGuardia's Terminal B on time and on budget is up to a team of engineers led by Carmela Cinicolo.

What's the completion date?

MAN: By the middle of next year.

Okay.

NARRATOR: Carmela and her team manage 30 different contractors and a $4 billion budget.

CINICOLO: In construction, it's dynamic.

It's constantly changing-- day in, day out, there's a new issue that arises while we close out a prior issue.

♪ ♪ NARRATOR: Working with Carmela to deliver the new Terminal B is Jessica Forse.

Today, Jessica checks on construction progress for the main terminal building.

It's a 24/7 operation, all hands on deck.

NARRATOR: It takes almost four years of intensive work to build up the enormous steel structure of the four-story terminal.

FORSE: Ultimately, what will be the most amazing about this area is really going to be the vistas, right?

The, the glass wall and the, and the view upon the airfield, and really just taking it to a whole new level-- the light and the, the experience for people that, that, to see the airfield through this kind of really very grand space.

We are probably just peaking out with overall volume of workers that we have in this location.

There's tons of activity.

NARRATOR: With the main terminal building and two satellite concourses taking shape, the team must connect them.

Building Terminal B's two vast pedestrian bridges could be their toughest challenge.

CINICOLO: The erecting of steel is to take place right now.

We're at that point in the schedule.

♪ ♪ NARRATOR: The team will use two different techniques to construct each bridge.

The eastern bridge will be built out onto shoring towers, one piece of steel at a time, to meet in the middle, 65 feet above the ground.

But the western bridge will be constructed differently.

They will build it in six massive sections on the ground from 2,500 tons of steel, then lift these vast trusses into place on top of the shoring towers.

The final two sections must fit with millimeter accuracy to complete the nearly 500-foot span.

Only then can the team remove the supports and clad the bridge.

MURPHY: The size of everything we're using is much bigger.

The steel is much bigger, the equipment is much bigger-- it can be nerve-racking.

I have-- I will admit, I've lost sleep on this project.

NARRATOR: Today, superintendent Dan Murphy must install the biggest truss on the entire airport build.

MURPHY: This is the heaviest pick on the project, all right?

And there is no other gang I want doing this than your gang, obviously.

NARRATOR: This is a critical job for Dan and his team of ironworkers.

They all need to bring their A game.

So, we pick this thing up, and if it is too out of whack vertically, we're going to talk about what we need to do in order to put this thing back down safely.

Hopefully, that's not the case, hopefully, it's on the money, but we've, we've been wrong before.

♪ ♪ CINICOLO: It all looks positive to go.

We're all excited.

It's the next phase of the construction, and all the stakeholders are here to witness it.

It's one exciting time.

(horn blaring) ♪ ♪ NARRATOR: The crane driver gently hoists the top of the 200-ton truss, gradually standing it up.

RAFIK MOAWAD: When you're tipping the big truss like this, it's also, is very important to make sure, you know, you got to tip it right and get it straight.

MAN: Easy, baby, easy, easy!

(machinery whirring) Easy!

(murmuring) Nice, nicely done!

NARRATOR: The first pedestrian bridge truss is upright.

Nicely done.

NARRATOR: And ready to lift into position.

But as the crane raises it off the ground for the first time, there's a problem.

MAN: We're way out, huh?

Jesus.

NARRATOR: The truss is now dangerously uneven.

It's higher by five-and-a-half feet at one end.

The load is unbalanced.

Try to lift it now, and the rigging bolts could snap, causing the truss to fall.

CINICOLO: When working with these large pieces of steel, there is really no margin of error.

NARRATOR: The team carefully lowers the truss back down horizontally and races to adjust the lengths of the crane-rigging cables.

CINICOLO: It's a balancing act.

There's risk factors there, so we have to make sure that the steel is perfectly balanced so that our crane operator has the level of comfort to raise it into its proper position.

♪ ♪ NARRATOR: With the rigging reset, the team attempts to lift again.

(metal creaking) MAN: Up we go.

NARRATOR: The crane raises the truss upright once more.

♪ ♪ MAN: Easy, easy, easy.

NARRATOR: It's the moment of truth, as the truss rises off its blocks.

MURPHY: Now let's see how bad it is.

It was six feet out before.

That's good, that's good.

NARRATOR: They've done it.

MURPHY: That's beautiful.

NARRATOR: The truss hangs straight and true, parallel to the ground.

That's better than third time's the charm, right?

(laughs) NARRATOR: The team uses two taglines to control the truss as the crane swings it around towards the shoring towers.

♪ ♪ The 115-foot-long truss rises 70 feet into the air.

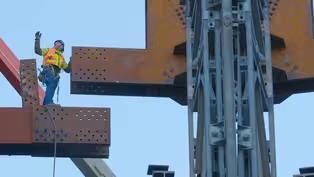

♪ ♪ Now these high-walking ironworkers must guide the steel into its proper location.

MOAWAD: The issue here is how we can align the three pieces and the three connection in the same elevation and the same time.

♪ ♪ Right now, we have two crew, one working this side and one working this side, and they'll try to align it.

NARRATOR: It takes over an hour to wrestle the 200 tons of steel into place and bolt the three connection points together.

The first of six massive trusses is in position.

♪ ♪ Now we can breathe-- now we can breathe.

♪ ♪ NARRATOR: This pioneering bridge begins to take shape high above the airfield below.

To the far east of the site, LaGuardia's Terminal C sits on a narrower and more compact parcel of land.

This creates a different set of challenges for the team tasked with constructing the new airport buildings here.

The Terminal C design will look radically different than Terminal B.

Project manager Manny Incorvaia leads the hundred-strong Terminal C design team.

INCORVAIA (chuckling): There's no more land.

We're just constrained everywhere.

There's no, you can't build in the water, environmental nightmares.

There's just no space.

We are penned in by the water on the north side and the Grand Central Parkway on the south.

NARRATOR: To make the best use of the limited space, the team must push Terminal C back to the eastern corner of the site.

They'll build three long finger concourses and one extra finger, Concourse G, on the edge of the bay.

This way, they'll have the 37 gates they need, and enough space for two-lane taxiways.

And that's one of the primary goals, is to put in dual taxi lanes, get them flexibility as much as possible at each gate.

INCORVAIA: I think it'll be a complete transformation.

Everything will be different.

There's nothing that's going to be the same.

It's going to be all brand-new, it'll be awesome.

You see that?

Now, now you notice it.

Yes.

NARRATOR: Program director Ryan Marzullo is tasked with keeping the construction of this vast terminal-- that has many moving parts-- on track.

New York needs a proper front door, front entrance, and a gateway to the greatest city in the world.

And so, we're going to go from, you know, being a joke to being a shining example.

NARRATOR: On the southeast side of the site, Ryan's team faces a particularly complex engineering challenge, to build Terminal C's Grand Entrance.

MARZULLO: We'll peak out at about 1,300 men and women on site building this new terminal.

The amount of work going on on a daily basis is absolutely phenomenal.

NARRATOR: This will be Delta Airlines' gateway to the new airport.

This façade will welcome almost 14 million passengers a year and lead them into a light-filled departures hall.

First impressions here count.

New Yorkers are very demanding and very opinionated, and we designed our facility around that.

NARRATOR: The grand entrance to Terminal C is designed to be both spectacular and to improve passenger flow.

A smaller curbside building will provide express bag drop and direct access to security in the main terminal via a footbridge.

Engineers could build a vast roof over the forecourt, but that would block light.

So, architects proposed a 15,000-square-foot opening called an oculus to flood the entrance with light.

It's an ambitious design that will present a particularly tough challenge to Ryan and the construction team.

MAN:: Come down a little bit more!

NARRATOR: The oculus is built from almost 400 pieces of interlocking steel.

The truss that sits across the forecourt roadways at the east end of the oculus weighs 80 tons.

This will be the biggest lift on the Terminal C project.

♪ ♪ Raising the truss in one piece, rather than in smaller sections, will save time.

Terminal C's complex phasing plan hinges on Ryan's team installing this truss before the roadways to the terminal can be built.

MARZULLO: We need to get this piece of steel, this massive piece of steel, this roof truss, up in the air to allow the roadways to continue.

So critical day, critical moment in the project, and it allows us to keep moving, because this is on the critical path.

DAVE WHITEHOUSE: We're gonna make one critical pick, pick it up, put it into place, slowly walk it in.

The whole thing should take six hours, so it's a, it's a little stressful.

♪ ♪ NARRATOR: Dave Whitehouse is under pressure to complete this lift earlier than planned to avoid a storm that's moving in.

Trying to lift during a storm could be deadly for the ironworkers.

Being out on this steel while it's wet, very dangerous.

You can't weld in the rain, because you get electrocuted.

Uh, so weather is definitely a big factor.

NARRATOR: And it's not just rain that's a concern.

Wind gusts could make the truss impossible to control.

TIMOVA: After certain mile-per-hour winds, the crane has to get shut down, because it's way too dangerous to have any pieces in the air.

NARRATOR: Dave's team feels the time pressure as they prepare the oculus steel for liftoff.

WHITEHOUSE: The ironworkers are working really hard.

They're working ten-hour days.

Everybody's trying to get this ready.

Time is everything.

NARRATOR: Terminal C's designers are making the best use of the limited space available.

But there's a particular problem with the location of this terminal building.

Its position on the bay makes the terminal extremely vulnerable to storms and flooding.

We're on a body of water.

So, what kind of flood designs do we need to take into account?

NARRATOR: Severe floods have devastated LaGuardia Airport in the past.

In 2012, Superstorm Sandy smashed the East Coast and plunged the airport into chaos.

GARY FRATTALI: The wind blew the water and the storm surge over the embankment, and that, we just became inundated with that.

When that happened, this entire area was flooded.

NARRATOR: An estimated 100 million gallons of water swept over the airport's storm wall.

Terminal C's network of concrete storm drains and its main pumphouse were completely overwhelmed.

♪ ♪ The flood shut down the airport for three days.

A quarter of a million passengers had their flights canceled, costing the airport over $1.1 million in lost revenue.

♪ ♪ Today, the design team must ensure that the new Terminal C can withstand anything Mother Nature throws at it.

INCORVAIA: The structural design will have to account for this flood-event wave action that can come and hit the building.

We don't want the building floating away.

NARRATOR: Concourse G will sit right on the water's edge, directly in harm's way.

The team must raise it up 20 feet onto concrete columns to allow any floodwater to pass harmlessly underneath.

MARCO CIPOLLETTI: When you are talking about Concourse G, that's definitely going to be a structural challenge.

The bottom floor cannot be occupied, and so we will have to design the structure to basically sit on columns and exposed, so that will be, need to be designed for a possible flood event.

NARRATOR: It takes 26 months to build the new 1,000-foot-long and 77-foot-tall Concourse G. ♪ ♪ Its glass walls give commuters a unique view of the bay, while its raised ground floor should prevent a storm from triggering a catastrophic inundation.

The team is engineering additional innovative features underground to prevent a superstorm from overwhelming Terminal C. They are constructing a brand-new five-mile-long storm drain network beneath the airport that should make it more resilient to flooding.

FRATTALI: What we're doing today is inspecting the drainage lines just to make sure that there's no debris, they didn't leave any sandbags during the construction effort.

Because it's plastic, but it's corrugated to give it the same strength as the old concrete.

I don't know about the durability of it yet, but we're going to find that out.

♪ ♪ NARRATOR: Engineers run checks through the network to ensure it remains free of any blockages or debris.

VITO LOGIUDICE: I'm a little claustrophobic, but I'd rather be there than up high.

You know... (laughs) I put a lot of trust into, to the guys I work with.

They can always pull me out if something ever happens.

So that's good.

(chuckles) I have been down where Vito is before.

I'd rather be up here now.

(laughs) Getting a little too old for that.

♪ ♪ NARRATOR: The team lowers a special camera, known as the sea snake, into the storm drain.

FRATTALI: That's tethered to a monitor.

I'm watching for the shape of the pipe.

It, it should be completely round.

I want to make sure that the ceiling has not collapsed down, where it makes the pipe oblong.

You can see that there's no, um, obstructions in the line.

NARRATOR: The sea snake has already helped the team locate some major issues in the new pipes.

FRATTALI: We have found two-by-six planks of wood, collapsed pipes, several sandbags, concrete that wasn't removed.

The sandbags would have stopped flow completely.

NARRATOR: The pipes should be clear, but today, the sea snake has found a blockage.

FRATTALI: The camera was underwater, so we couldn't see what it was, but we pushed whatever it was into the manhole, because when we pulled the camera back out, the water was gone.

So we cleared the line.

So I don't know what it was, but it worked.

(laughs) NARRATOR: The team can come up for air.

They've checked almost 800 feet of pipe today.

Just another 26,000 to go.

Today is a critical day for Terminal C's ironworkers.

They will lift and install the massive truss that forms part of the oculus for the main terminal's grand entrance.

WHITEHOUSE: This is like a big high-profile milestone for the project.

So last night, my wife put the plate of food in front of my face, and I just, just played with it a little bit.

I was a little stressed out, slept for about two hours.

NARRATOR: Moving the schedule earlier to avoid the impending storm has paid off.

Conditions right now are close to perfect.

JARED KRAUSE: Slight breeze, but beautiful day to do this type of operation.

NARRATOR: Even so, lifting an 80-ton truss up 100 feet into the air is not easy.

This job falls to crane operator Matt Hayes.

HAYES: The biggest challenge is moving the crane, and the piece is going to be moving.

So, it's swinging back and forth, it could possibly hit the boom if it got out of control, which could actually collapse the boom, which would be a major problem.

♪ ♪ NARRATOR: But lifting the truss isn't the only challenge the team faces.

They must also bolt it into place at roof level.

The roof of the grand entrance is not yet reinforced.

A hole allows workers access to connect the truss.

Only once the truss is in position can they reinforce the entrance structure to take the full 80 tons.

The crane will hold the truss steady as ironworkers race to bolt 12 extra steel beams into position.

Nice and easy, all right?

(workers shouting) NARRATOR: With the team assembled and the truss hooked up to the crane... (horn honking) ...the biggest lift on the Terminal C project begins.

The only thing that's left is really for the crane operator to do his magic.

NARRATOR: The 100-foot-long steel monster ascends.

MAN: Keep pulling on it, keep pulling on it!

♪ ♪ NARRATOR: It takes a nerve-shredding 30 minutes for the team to hoist the truss 100 feet into the air.

Now the ironworkers must bolt it into place.

TIMOVA: My job is to make sure that it's safely guided into the point that it has to connect to.

And I am securing it once it is in place.

NARRATOR: One of more than 20 ironworkers connecting the gigantic steel truss is Ana Timova.

TIMOVA: I was a barber before this, and when I first heard about ironwork, I was, like, I don't want to go out on a dirty construction site, wear a hard hat, and be outside in the cold.

Now I, I love it.

Your first time up on the steel with, you know, nothing underneath you and about five inches to walk on, it's awesome.

I love the history, you know?

Here at New York, we had the, you know, the Flatiron Building.

We have the Empire State Building, the Brooklyn Bridge.

That's all built by ironworkers, and it's an amazing history.

NARRATOR: New York ironworkers have shaped and reshaped the city's famous skyline over the decades.

They honed their daredevil sky-walking skills during the boom in skyscraper construction in the early 20th century.

TIMOVA: Just to know that I'm part of that history, it's an amazing feeling, it really is.

WHITEHOUSE: You couldn't pay me enough to do what these guys do.

These guys, I think, would do it for free, and I wouldn't do it for all the money in the world.

(laughs) MAN: All right, should be good there.

NARRATOR: Ana and the ironworkers must guide the oculus truss so it slots into three connection points on the main terminal building.

Five inches!

(metal connects) NARRATOR: Touchdown!

The truss finally soars over the grand entrance.

Seeing that big 160,000 pounds of steel go up is pretty amazing.

NARRATOR: But just a single slender beam takes the enormous weight of the frame.

The team must now work quickly to bolt the reinforcing steel beams into position.

KEN CHASE: We have to install the rest of the steel, and that is the more support and more strength.

NARRATOR: Ironworker Ken Chase races to deliver bolts to his crew.

MAN: What do you need?

MAN 2: I need shorties.

(man exhales) MAN 1: How many do you want?

Right on.

You want those bolts in there, too?

Communication is essential-- essential.

(clanging loudly) There's so much banging around, you start to lose your hearing.

(clanging loudly) I have!

(laughs) Started to lose it, that is.

Hearing, that is.

(chuckles) (clanging loudly) NARRATOR: The first bolts for the reinforcing steel are now in.

But every minute the truss hangs in the air is another minute of danger.

CHASE: Many things could go wrong.

We could have rigging failure, for one thing.

That's just a cataclysmic event.

A lot of people that can be potentially...

Killed, you know?

Plain and simple, yeah.

NARRATOR: Ken's team can't make any mistakes as the oculus truss hangs in the balance.

TIMOVA: And it has to be done quickly, especially because the piece is in the hook already.

So they can't just say, "Okay, guys, hold on, let's put it down while they fix it up there."

♪ ♪ NARRATOR: They must work quickly to position all 12 reinforcement beams.

Now the oculus is in place, it's sitting down, they're going to make the connections.

NARRATOR: To connect the truss to the main terminal building, ironworkers must now install 200-pound steel keeper plates.

This calls for some serious muscle.

TIMOVA: Even the strongest guy is not going to lift one of these plates up by themselves and move it, so we set up a come-along to move the plate over and slide it so that the piece can fit into its little pocket.

NARRATOR: This ratchet, known as a come-along, helps force the plate into position.

CHASE: We have to finagle it, as they say.

It's almost like, you got to just, like, squeeze it in, you know?

TIMOVA: Now it's just making sure that the plate fits properly, all the holes line up.

Some people are, like, "Oh, you just go, you stick a bolt in a hole, and that's it."

It's not, it's, like, a lot of science that goes into it.

There's a proper size bolt that has to be in there.

There's a certain amount of threads that have to show or can't show.

There's a proper tension that each bolt has to have.

NARRATOR: As Ana and the team thread the final bolts through their holes, Dave can start to relax.

WHITEHOUSE (chuckling): I was worried about it all night last night, didn't eat too much.

But everything went great.

I feel like I'm hungry.

(laughs): I'm, it's time to eat.

But everything went great.

♪ ♪ NARRATOR: The eastern truss is secure, and the crane can release the full 80-ton load.

WHITEHOUSE: The oculus is up, nice and tight, everything's good.

NARRATOR: The grand entrance is taking shape.

Now work on the next phase of construction-- the arrivals and departures roadways-- can begin below.

TIMOVA: When you're part of a big project like this, it's something that for years, you're going to be able to see it.

Or if somebody ever says, "Hey, I'm flying out of LaGuardia," like, "What terminal?

Oh, I built that."

You know?

Like, it's, it's an awesome feeling.

NARRATOR: In just 30 days, the western oculus truss is in place.

The construction team has realized the vision for the entrance to Terminal C. ♪ ♪ As old buildings are demolished, and new ones built, the layout of the airport evolves constantly, changing over a hundred times since work first began.

Every chance we get to capture some real estate and build, that's what we do, keeping the facilities operational, keeping the aircraft moving, keeping the people moving, keeping the cars on the roadways moving.

Been a very complex puzzle that we've had to solve.

So what we do here is, we build something new, and then we tear down the old, and then we build something new, and then tear down the old.

NARRATOR: The challenge of keeping passengers and planes moving here is made even tougher by the extreme weather that strikes this exposed airport.

GILLEN: We live and die by the forecast.

Three days ago, the, it was looking only like an inch or two of snow, and now we're looking at over a foot.

NARRATOR: Tonight, the airport's chief of operations, Kevin Gillen, and his team are gearing up to battle their biggest snowstorm in five years.

GILLEN: We're expecting, like, serious blizzard-like conditions, heavy winds, heavy snow.

NARRATOR: With construction activity at full speed, the arctic conditions slow down building work and bring air traffic to a standstill, grounding almost 200 flights.

This is the team's worst nightmare.

It's up to Kevin and his crew to get the airport back up and running as soon as possible.

All right, good morning, everyone.

I'm sure everyone knows we're in snow condition five.

DIONNE SYPIOE: Snow has always been equivalent of work for me.

So, no, I don't, I don't necessarily get a joyous feeling when I see snow in the forecast.

(laughs) We're going to get a lot of blowing snow.

We're talking about 15 to 25 miles per hour with gusts of 40 to 50 miles per hour.

NARRATOR: Dionne Sypioe will coordinate the mission to clear the runway with Kevin.

She is in charge of 20 operations supervisors and 30 plow drivers.

(engine running) NARRATOR: Dionne dispatches four multifunctional snow plows to the runways.

Construction constantly changes the boundaries of the taxi lanes, potentially placing new fences and machinery in the path of the plows.

GILLEN: The airfield itself has changed dramatically in the past 12 months, so now the drivers find themselves in places when there's whiteout conditions that they're not used to being.

NARRATOR: Extreme weather is an ever-changing challenge for operations teams at airports like LaGuardia.

New York can be hit by brutal winter storms and sweltering summer heat waves.

ELLIOTT: New York has four seasons, supposedly.

You just don't know when, when that season is going to occur.

NARRATOR: For New York's new LaGuardia Airport, a fail-safe way to both heat and cool the hub is crucial to keep planes and passengers moving.

COTTON: Future-proofing a facility has to be a central guideline in terms of how you build it.

NARRATOR: So the airport's new Terminal C features an innovative engineering solution.

An electrical substation built into the airport terminal generates enough power for around 8,000 homes.

It also packs in six enormous boilers to heat the interior spaces in winter.

And to cool the terminal in New York's scorching summers, there are five high-powered chillers and 65 huge ice storage tanks.

Heating and cooling the old building was like trying to heat and cool your house with the windows open and the stove on.

NARRATOR: But that's all changed.

The new system is groundbreaking.

Temperature sensors give engineers Robert Rovelli and Mike Alfano real-time information throughout the new terminal.

ROVELLI: If one area is hot within a 50-foot area, we can literally see that on our computer screens and adjust just that area.

NARRATOR: Today, the system will be pushed to the limit.

A state of emergency has been declared.

The snowstorm has caused temperatures inside the terminal to plummet.

We got some cold temperatures on the connecting bridges, wow.

It's cold.

Let's ramp that up.

NARRATOR: Mike heads over to check on the six vast boilers.

ALFANO: Today is brutally cold out there.

(wind whipping) The wind is howling, so that is the challenge of the day, is making sure the boilers stay online and we keep the place warm.

These parti... (alarm beeping) Ah, we just had a failure!

NARRATOR: The primary boiler has failed.

Outside air feeds the boiler flame, but the savage storm winds are forcing too much air in through the vents, blowing out the pilot flame.

I need to get a boiler up online A.S.A.P.

(alarm beeping) NARRATOR: They must urgently get heat back into the system.

ALFANO: If I can't get another boiler to come on, my hot water temperature is going to start dropping, and that's where stress will start to come in.

(alarm beeping softly) Trying to fire up.

And we were lucky.

(alarm beeping loudly) No, we lost it!

NARRATOR: The heat is on Mike.

I'm going to make sure that this boiler runs at a higher firing rate, giving me a better chance that the wind can't blow it out.

NARRATOR: Mike doubles the boiler flame size.

And it works.

The howling wind outside can no longer blow out the boiler.

We come together as a team.

That's why we call each other brothers.

We are the unsung heroes.

♪ ♪ NARRATOR: Outside, on the frozen airfield, Kevin and Dionne check that the clearance of the two runways is on track.

♪ ♪ CHRISTOPHER CLIFFORD: We got about 18 to 24 inches coming in.

This is the worst storm we've had in a few years.

Right now, we're going up and down, making sure there's no snow and ice build-up.

NARRATOR: These mammoth machines weigh over 28 tons each and can clear almost four million square feet per hour.

SYPIOE: If we were to allow the snow to accumulate, that would increase our chancing of icing on the runways and taxiways.

♪ ♪ NARRATOR: As night falls, the storm finally clears New York.

Thanks to Kevin, Dionne, and the team, the first planes can safely land in the morning, and construction work can resume on the $8 billion redevelopment.

GILLEN: Fortunate enough to have a young staff here who's anxious to chomp at the bit at a storm like this, to get this airport back to where it belongs.

♪ ♪ NARRATOR: Across the site, construction work on the new main Terminal B building is progressing at high speed.

FORSE: The biggest challenge is just the volume of things that are left to do and the amount of different people that have to do them.

NARRATOR: Lighting and electrics are now installed, the walls of the departures hall are plastered and painted, and the brand-new tiled flooring has been laid.

FORSE: We've just come into the departures hall.

As you can kind of see, all the ticketing islands kind of up and ready to go.

You can imagine yourself coming in, checking in for your flight.

NARRATOR: As the inside of the main terminal building nears completion... ♪ ♪ ...outside, the team is under intense pressure... ...to complete the 2,500-ton, 450-foot-long bridges that connect the terminal to the new gates.

The eastern bridge is now complete and connects the main terminal building to the eastern gates.

Today, they must haul the connecting truss of the western bridge into place.

This will complete the span.

It's a major milestone.

MOAWAD: Very exciting, very exciting.

Oh, come on, this is the last one, very exciting.

NARRATOR: The crane holds the truss just above its connection points.

As the ironworkers get into position... MURPHY: Look at these clouds coming in, you gotta be kidding me.

NARRATOR: ...Mother Nature throws superintendent Dan Murphy a curveball.

MURPHY: We've got the truss assembly up in the air.

The wind has picked up, which is not good.

NARRATOR: It's now a race against the elements to install the truss before the team loses control.

MURPHY: I'm not, uh... (horn honking) Not liking what I'm seeing.

Watch the boom.

Watch the boom!

(metal creaking) If we gotta take it out, take it out.

NARRATOR: The wind threatens to blow the bridge truss installation off course.

Dan and his ironworkers must act fast.

It needs to be level to come straight down and not get hung up on anything, not touch anything.

NARRATOR: The truss slides down into the connection plates on all four corners.

The team tightens 240 bolts.

♪ ♪ NARRATOR: They've finally completed the steel span.

And the very first pedestrian crosses the new bridge.

MURPHY: All of those components coming together to make this successful is...

It's why we come to work, really.

♪ ♪ NARRATOR: Over the next 20 weeks, they clad the steel trusses and install more than 400 panels of glass to enclose the bridge.

It's a huge achievement for the Terminal B team.

It is a significant milestone.

I'm very proud of the guys.

♪ ♪ NARRATOR: Inside, the team is completing another major landmark for the project-- the installation of the airport's vast new baggage system.

The new airport must be able to process 40 million bags each year.

Getting the right bag to the right aircraft requires an ingenious system.

ANGELO SALGADO: Each bag is given a bag tag.

This bag tag becomes basically the license plate of the bag.

This bag tag has a unique identifier that will then be tracked throughout the entire system.

NARRATOR: A network of scanners reads the tags and automatically directs the bags left or right to the correct loading bay.

Vertical sorting units also move bags up or down a level, if needed.

Before all baggage moves airside, the conveyors shuttle it through security.

The new state-of-the-art technology that we have in security can pick up anything, but if it picks it up, it's dealing with it, dealing with it swiftly.

NARRATOR: With up to 6,000 bags to check every hour, how can engineers ensure a suspicious bag is not sent onto the aircraft?

Special explosive detection machines scan every bag.

If they raise a red flag, bags are rerouted to TSA agents on the lower floor for hand checking, while cleared bags must go up a level to reach the gates.

NARRATOR: Vertical sorting units-- VSUs-- are an essential part of the security system.

Their conveyors divert the bags either up or down, depending on whether they are cleared or not.

The VSUs automatically ensure a suspicious bag never makes it onto an aircraft, keeping the skies safe for passengers.

It's protection of life, protection of property, then resume operations.

♪ ♪ NARRATOR: It's now a race to the finish line for Jessica and the Terminal B team to complete all elements of the fit-out.

Workers battle to wire up the vast network of lights, install more than 3,000 seats and 250 toilets, and lay more than 80,000 square feet of carpet.

FORSE: I feel relieved.

It's a really great accomplishment.

It's nice to see all the hard work and all the planning works exactly as you've drawn it up.

♪ ♪ NARRATOR: It takes four years of painstaking planning and relentless construction... ...but now LaGuardia's first new terminal is finally ready to welcome passengers.

VERO: Each milestone we were able to deliver to the public, they started to see the transformation.

And today is just one more in that series of steps.

And it's, it's just great for all of us.

NARRATOR: Terminal B now has 850,000 square feet of light-filled space, with streamlined check-ins... ...custom artworks, and large cafés.

Departure lounges now offer modern, spacious rest areas for even the most discerning New York traveler.

COTTON: They're walking into a facility which has 55-foot-high floor-to-ceiling glass, art, an enormously appealing, modern, global-standard facility.

And just to see the surprise on their faces was very striking and very satisfying.

FORSE: It's been a very long project, so to see all these accomplishments over time and celebrate them is really important to keep the motivation up and going.

♪ ♪ NARRATOR: Outside, with the new taxiways complete, the team gathers to celebrate another major milestone.

The first aircraft will finally pass beneath the 65-foot-high eastern bridge, and planes will have more access to and from the gates of the new terminal.

The twin bridges represent a world first.

Never before has an airport used two bridges over active taxiways.

They will revolutionize operations at Terminal B, allowing aircraft greater flexibility to taxi around the airport, reducing delays.

COTTON: If an airplane is coming in from one direction, the departing aircraft can be pushed out and leave in the other direction.

So, you should never hear a pilot again at LaGuardia say, "I'm sorry, we can't push back because there's an airplane blocking our alleyway."

VERO: So many different entities are part of a multibillion-dollar project like this.

And it's just so important to take a minute and celebrate the wins, celebrate the victories.

Everyone is filled with pride today.

♪ ♪ NARRATOR: The brand-new Terminal C opened in 2022, with construction on the last gates finishing up about two years later.

♪ ♪ Altogether, it takes more than eight years, $8 billion, and a unique vision to transform LaGuardia from America's worst airport to one of its very best.

♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪ ♪

The $8 Billion Overhaul of LaGuardia Airport: Engineering a New Era

Video has Closed Captions

Clip: S52 Ep2 | 2m 12s | Discover how an $8 billion transformation turned LaGuardia into a state-of-the-art facility. (2m 12s)

Extreme Airport Engineering Preview

Video has Closed Captions

Preview: S52 Ep2 | 30s | Follow the race to build a world-class airport on the site of one of America’s busiest flying hubs. (30s)

What Happens to Your Checked Bag at the Airport?

Video has Closed Captions

Clip: S52 Ep2 | 2m 34s | Getting the right bag to the right plane requires an ingenious system. Here’s how it works. (2m 34s)

Providing Support for PBS.org

Learn Moreabout PBS online sponsorship

- Science and Nature

Capturing the splendor of the natural world, from the African plains to the Antarctic ice.

Support for PBS provided by:

Additional funding for this program is provided by the NOVA Science Trust with support from Margaret and Will Hearst and the Hoveida Family Foundation. National Corporate funding for NOVA is...